Unleashing Potential: Advantages of Plastic Injection Molding Technology

Plastic injection molding technology has completely transformed the manufacturing landscape, offering numerous advantages for enterprises to efficiently and cost-effectively produce high-quality plastic components. Here are the reasons why plastic injection mold technology has become the preferred method for manufacturing plastic parts:

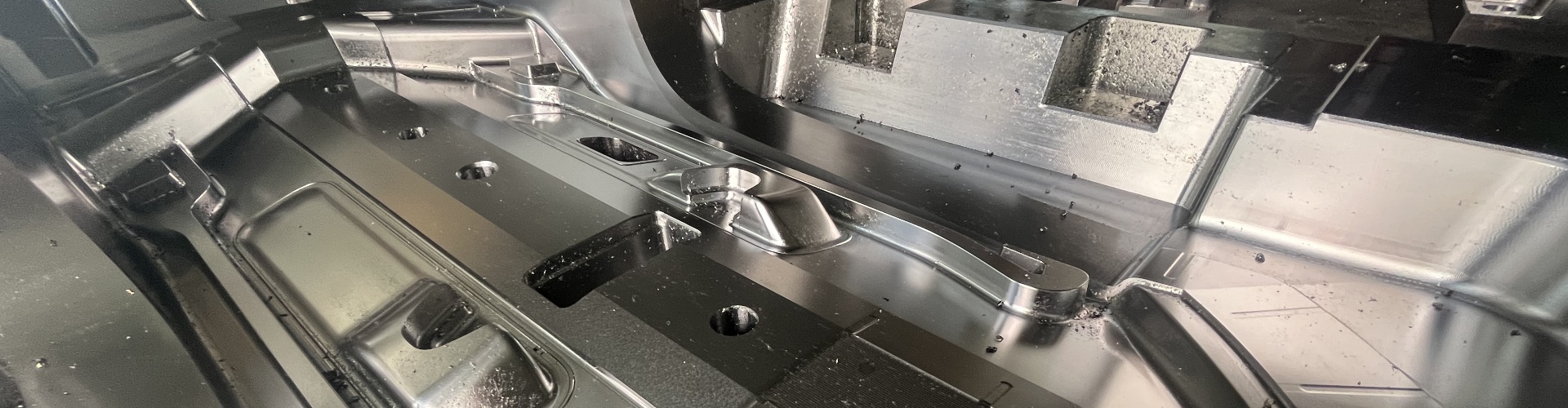

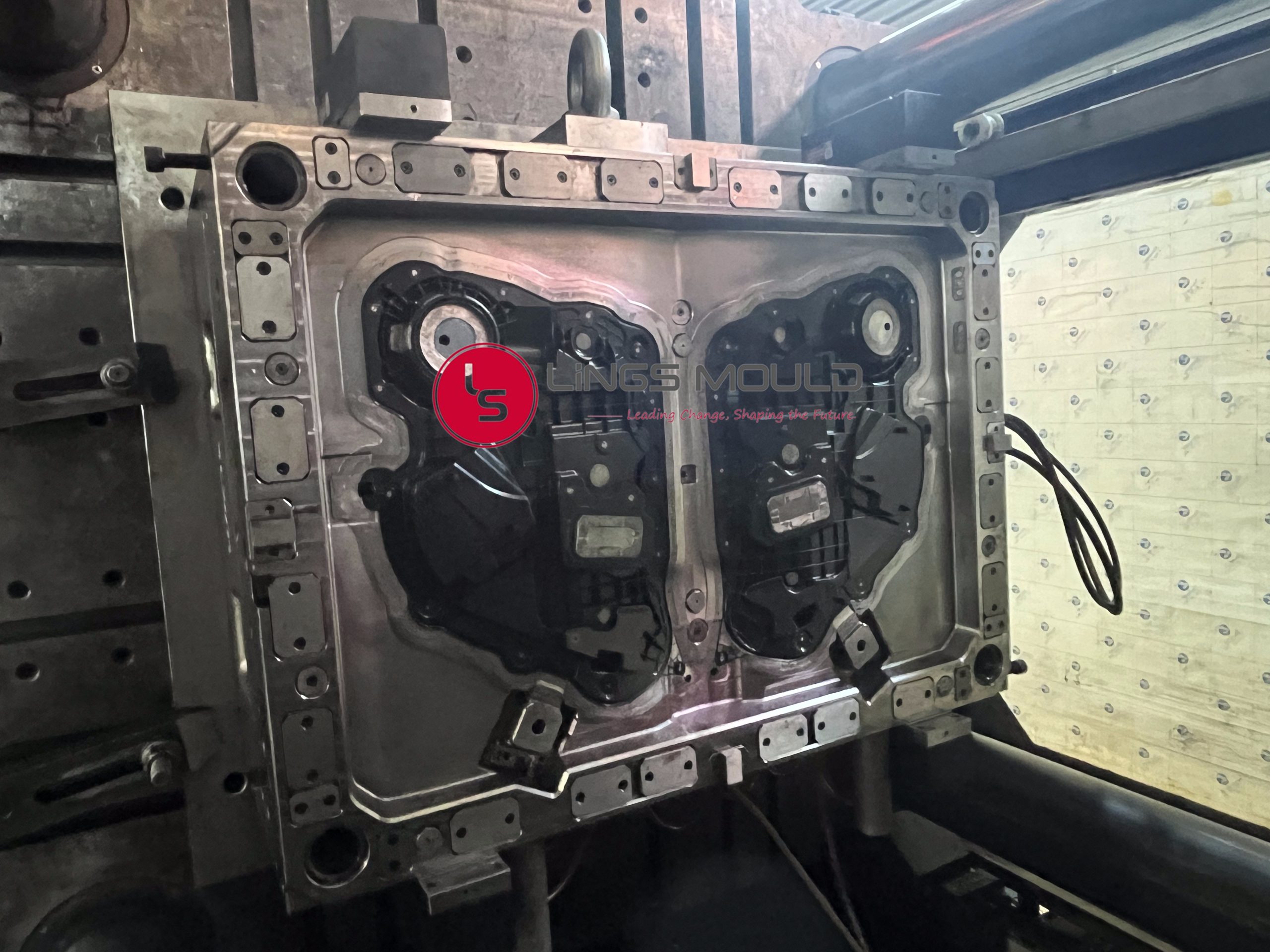

- Precision in Complexity: Plastic injection mold technology excels in accurately crafting complex components. By injecting molten plastic into molds and allowing it to cool and harden, businesses can produce parts with consistent quality, precise tolerances, and intricate geometries.

- Scalability and Efficiency: This method boasts high scalability and efficiency, easily automated for rapid part production. Streamlining the manufacturing process through automation reduces production costs and accelerates delivery times, making it an economically viable solution for mass production of plastic components.

- Lightweighting in Automotive Parts: Plastic injection mold technology also offers significant advantages in lightweighting automotive components. By utilizing lightweight plastic materials to manufacture automotive parts, companies can effectively reduce overall vehicle weight, improve fuel efficiency, and minimize environmental impact. The lightweight application of plastic materials provides automotive manufacturers with greater design flexibility and performance advantages.

- Environmental Sustainability: Plastic injection molding generates minimal waste, which is easily recyclable, contributing to environmental sustainability. Its energy-efficient nature makes it a responsible choice for companies aiming to reduce their carbon footprint and promote sustainable practices.

Plastic injection mold technology provides numerous advantages for enterprises seeking rapid, cost-effective production of high-quality plastic parts. Across various industries, this technology is favored for its efficiency, versatility, and environmental friendliness. Leveraging the advantages of plastic molding technology propels businesses towards greater success and innovation.