Our Project managment

1.RFQ

Please provide the following data when requesting for quotation, and we will offer a reasonable quotation to you.

1.1. 2D (dwg/dxf/pdf/tif) & 3D (stp/step/igs/x_t) part drawing, or sample.

1.2. Requirement on cavity number, plastic, output quantity, surface finish. cold runner or hot runner system. please tell us manufacturer if you use hot runner system.

1.3. Please tell us an appointed steel material. If no, we will choose a suitable type based on your requirement on mold output quantity.

2.Order

2.1. When you are satisfied with our quotation and facility, we can sign contract for cooperation.

2.2. You can either send PO via email or facsimile.

3.Project Management

3.1. Recived the receipt of PO from you. Firstly a series of engineering analysis will be carried out to your part drawing, including part &. mould structure analysis and Moldflow analysis etc.. Through analysis we can discover the disfigurement on part design, and propose on improvement, or send modified drawing for your confirmation.

3.2. Then we will start 3D mould layout design. Normally it takes 3~5 days to finish it.

3.3. We will modify the mould layout after receiving your comments, till your approval on the final design.

3.4. We will start ordering steel and mould base, and start 3D mould design upon your confirmation letter on our mould design.

3.5. Normally it takes 3-10 days to finish the 3D mould design, we will send the 3D data to you after it.

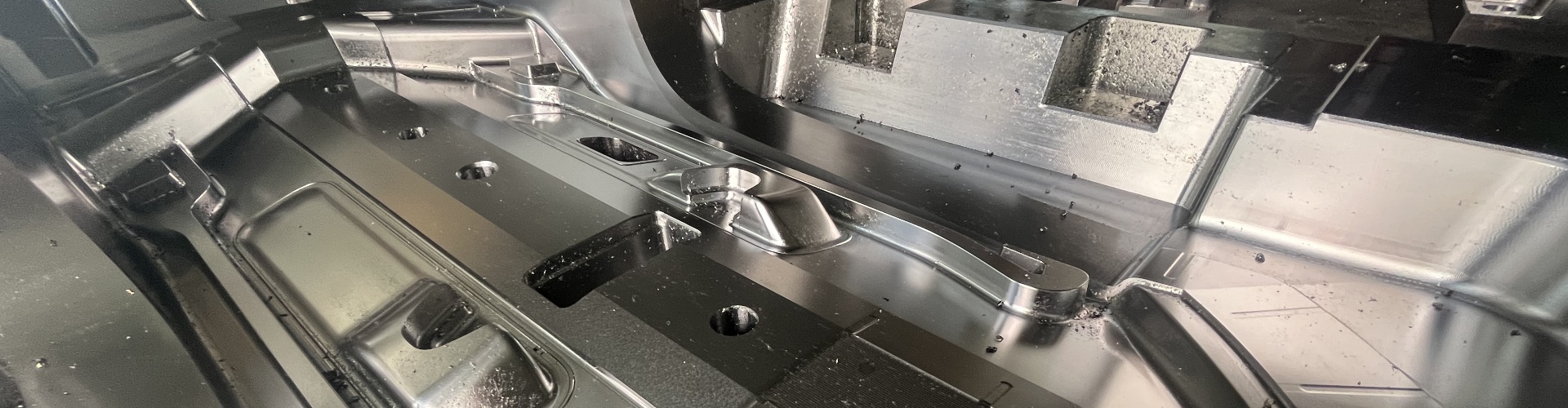

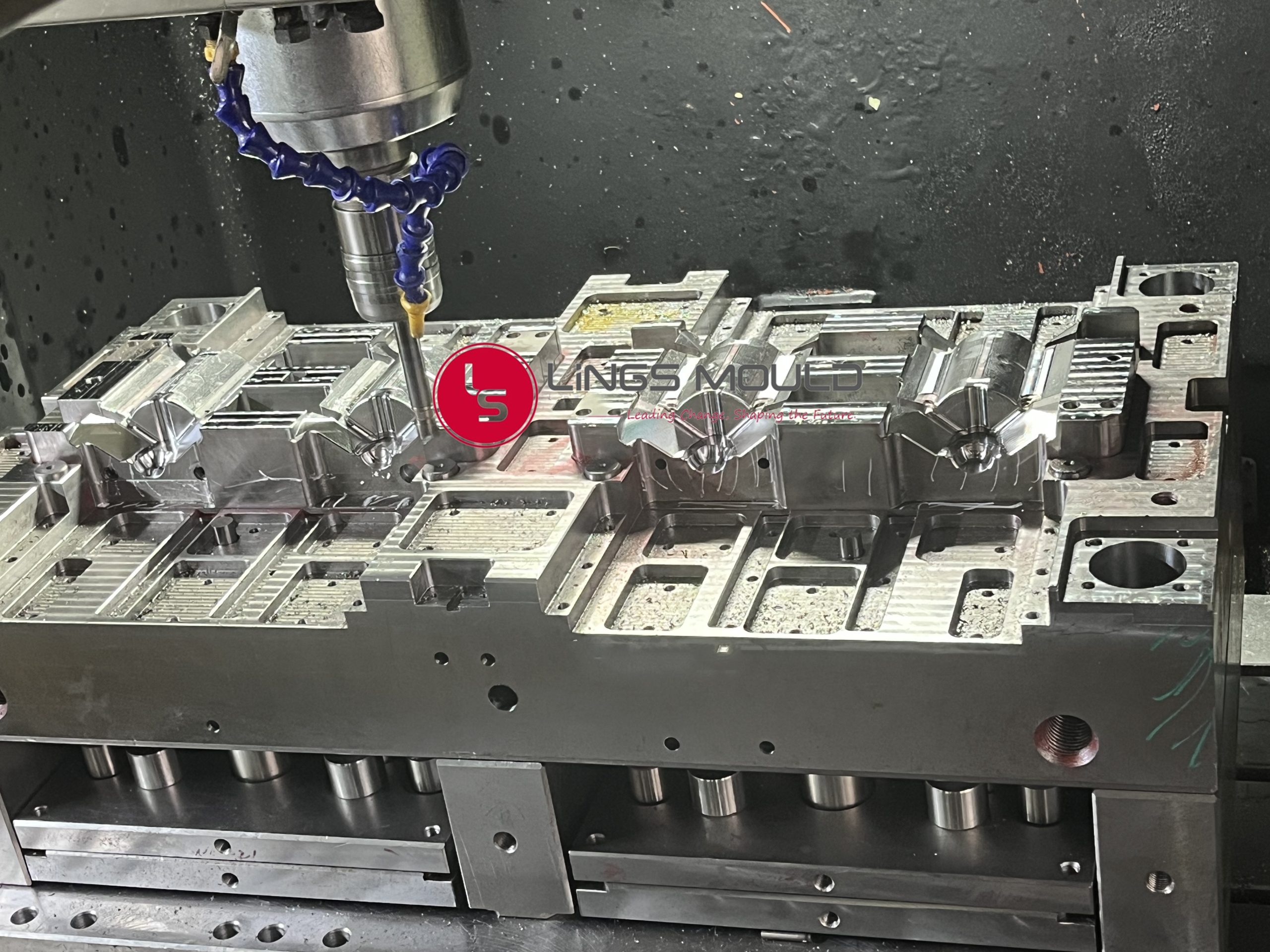

3.6. After 3D mould design finished, CNC programming will be followed immediately, and all the 3D component drawings will be transformed to 2D drawings with full mark of dimensions. Our toolmaker will carry on machining according to 2D component drawings.

3.7. we will send a timetable to you after your approval on mould design, and from then a weekly report with live pictures will be sent.

3.8. We will record T1(the first trial), and share you pictures and video of the process. After T1, we will send you samples.

3.9. After T1, we will optimize the mould according to our inspection and any feedback from you.

3.10. If any specific surface finish is required, upon your approval on the sample, we will arrange mirror polishing or texture. Afterwards, new samples will be sent to you for reviewing and approval.

3.11. Upon receiving your final confirmation on the sample,if the mould is going to be exported, we will start the preparation work for shipment,like movements nitriding, final inspection of cooling line, oil line and electronic devices.etc…

4.Project Management

Following documentation will be provided together with mould shipment:

4.1 material certificate of core/cavity and heat treatment report certificate (harden steel only).

4.2 3D and 2D latest data.

4.3 sample inspection report from final mould trial.

4.4 mould testing video and parameter record.

4.4 package and container loading photos for your custom clearance. etc…